Simply put, there is no such thing as “bulletproof glass”. Anyone who says otherwise is trying to sell you something. A more accurate term to use when discussing protective glazing is “bullet resistant glass”. Many times even that term is a misnomer since the majority of bullet resistant glazing products are a blend of polycarbonate or acrylic material.

Bullet Resistant Acrylic plastic refers to a family of synthetic, or man-made, plastic materials containing one or more derivatives of acrylic acid. The most common acrylic plastic is polymethyl methacrylate (PMMA), which is sold under the brand names of Plexiglas, Lucite, Perspex, and Crystallite. Source: Wikipedia

In general, ½” of acrylic (AKA Plexiglas) is considered to be bullet resistant. As with all ballistic tested and rated products, the thicker the material the greater the ballistic protection. To meet UL 752 standards Plexiglas needs to be 1.25” – 1.375” thick, depending on the type of round/bullet, the gun fired and its muzzle velocity.

Polycarbonate, (aka Lexan or Makrolon) or specifically polycarbonate of bisphenol A, is a clear plastic used to make shatterproof windows, lightweight eyeglass lenses, and such. General Electric manufactures polycarbonate and sells it as Lexan. Polycarbonate gets its name from the carbonate groups in its backbone chain.

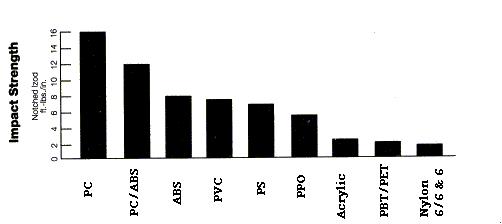

According to the chart below (Courtesy of Creative Mechanisms), polycarbonate’s impact strength is more than 4 times that of acrylic.

Polycarbonate has been proven a safe and effective material for stopping multiple rounds fired into a concentrated pattern from all sorts of handguns, hence its use for UL® bullet resistant rated glass.

The two most common types of bullet resistant glass are “No Spall” or low “Spall Glass”. Underwriters Laboratory (AKA UL®) has a product specification and testing procedure for No Spall glass. UL® has polycarbonate on one side only. HP White approved Low Spall glass sandwiches a sheet of polycarbonate with glass on both sides.

A picture is worth 1,000 words. The UL® approved product on the lower left demonstrates its effectiveness against spalling, as the glass is only on the “attack” side, not the “witness” side. The HP White approved product on the lower right shows the glass spalling on both sides. This is due to glass being on both sides. Both products stopped the bullets. The UL® is designed and effective in keeping all chards of glass on the “shooter side”. The HP White’s product design projects chards of glass on both the shooter and witnesses sides.

Call us today at (720) 545-2816 or email us at info@isotecinc.com to learn more!

UL® type bullet resistant glass is more expensive than HP White, but note that the Department of Homeland Security specifies the need for UL® 752 no spall glass for use in certain anti-terrorism technologies. These photos show why:

We look to the laws of physics when considering bullet resistant specifications. E = (M x V²) ÷ 450,435 is the formula used to calculate the energy from bullets. Don’t worry, I missed that class too. In layman’s terms, a fast and heavy bullet packs a larger wallop (greater energy) than a slower lighter bullet. So stopping a bullet from a 9mm or a .40caliber handgun requires a greater thickness of ballistic material that will be needed for stopping a .38 caliber gun.

The devil is always in the details when considering the bullet resistant product specifications. It always comes down to the numbers, and each facet of bullet resistant protection has its own special set of numbers.